MANUFACTURING SOLUTIONS

MANUFACTURING SOLUTIONS

At the forefront of modern manufacturing, customized tools, reverse engineering, and rapid prototype parts offer tailored solutions to meet specific operational demands and enhance product development processes.

Modern efficient manufacturing processes in

- Customized Tools

- Reverse Engineering

- Rapid Prototype Parts

Customised Tools

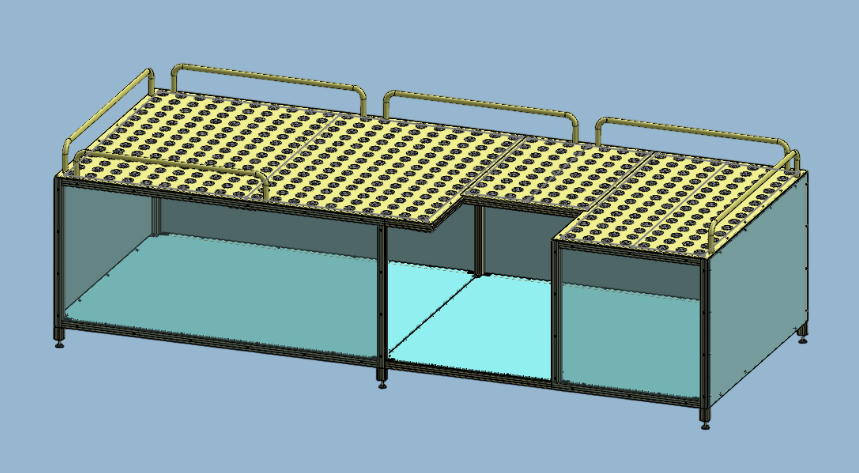

Customised tools are engineered to meet the unique requirements of specific tasks or industries. These tools are designed with precision to optimize productivity, minimize downtime, and ensure high performance in challenging environments. They can range from simple hand tools to highly sophisticated machinery components. Customisation is often driven by the need for enhanced efficiency, the handling of specialized materials, or the execution of complex operations that standard tools cannot accommodate.

Key Benefits:

- Tailored to specific operational needs, ensuring optimal functionality and ease of use.

- Increases productivity by reducing setup times and improving precision.

- Durable and cost-effective, designed to withstand harsh working conditions.

Reverse Engineering

Reverse engineering is the process of deconstructing and analyzing existing products or components to understand their design, functionality, and manufacturing processes. This technique is particularly valuable when dealing with legacy systems or when the original design files are unavailable. By creating accurate digital models from physical objects, reverse engineering allows for the redesign or enhancement of components for improved performance or compatibility with modern systems.

Key Benefits:

- Enables the reproduction or improvement of obsolete or discontinued parts.

- Facilitates the creation of parts that align with current standards or innovations.

- Assists in the development of custom solutions for integration with new technologies.

Rapid Prototype Parts

Rapid prototyping is a method used to quickly fabricate a model or prototype of a part using 3D printing or other additive manufacturing techniques. This approach significantly accelerates the product development cycle, allowing designers and engineers to evaluate the form, fit, and functionality of a part before full-scale production begins. Rapid prototyping reduces the time and cost associated with traditional prototyping methods, enabling faster iteration and optimization of designs.

Key Benefits:

- Accelerates the design validation process, enabling faster time-to-market.

- Provides a cost-effective method for producing functional prototypes with complex geometries.

- Enhances collaboration by allowing for tangible, testable models to be produced quickly.

Together, these advanced manufacturing techniques offer a cohesive solution to modern engineering challenges, driving innovation while reducing costs and time-to-market. Whether through the customisation of tools for specific applications, the application of reverse engineering to unlock or improve existing designs, or the use of rapid prototyping to bring concepts to life swiftly, businesses can achieve higher efficiency and precision in their manufacturing processes.